Imagine a world where the jewelry of your dreams can be created from scratch, in any design, and within hours, not days or weeks. Now, stop imagining. We’re already living in this world, thanks to 3D printing technology. From earrings to pendants, from bracelets to rings, 3D printing is reshaping the way we design and manufacture jewelry. This revolutionary technology applies not just to creating exquisite designs, but also to innovating the uses of a diverse set of materials, as well as streamlining the manufacturing process. Yet, like any good story, the saga of 3D printing and jewelry has its ups and downs, twirls, and turns. Let’s embark on this journey to uncover the wonders, benefits, real-world examples, challenges, and the potential future of 3D printed jewelry.

The Basics of 3D Printing Jewelry

3D Printing Technology Basics

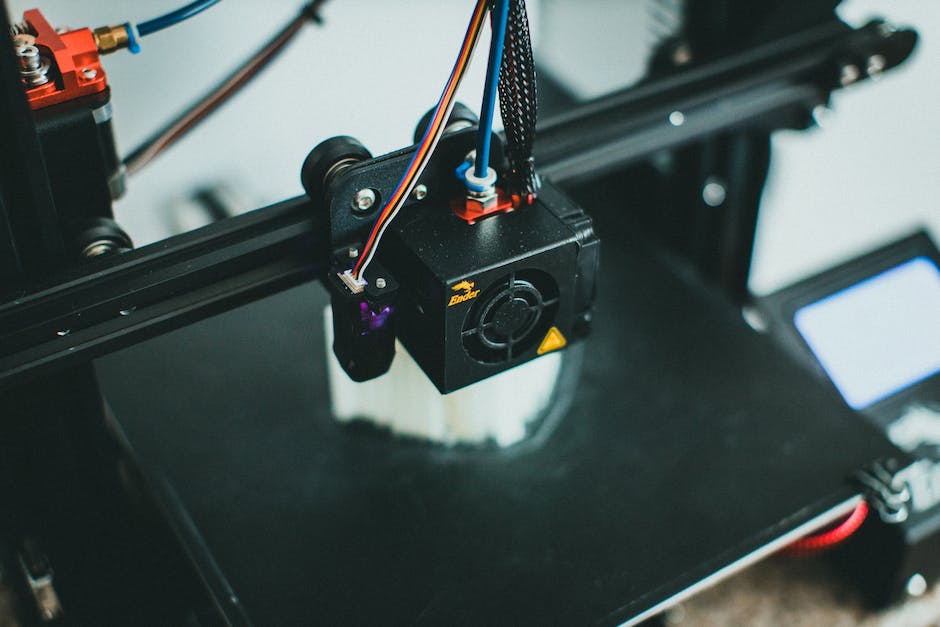

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. It involves layering materials together until the object is formed. This process is highly accurate, enabling the creation of detailed, intricate pieces without the manual labor typically required in traditional molding or casting processes.

Types of 3D Printers Used in Jewelry

There are primarily two kinds of 3D printers that are currently widely used in the jewelry sector, namely Stereolithography (SLA) printers and Direct Metal Laser Sintering (DMLS) printers.

SLA printers are popular for jewelry making because they can produce extremely precise and high-resolution items. These printers use a vat of liquid resin, which solidifies under a laser to create the desired object.

On the other hand, DMLS printers use a laser to sinter powdered metal, fusing it into a solid part by melting it together. This technology can work with a variety of alloys, making it versatile for jewelry projects.

Compatible Materials with 3D Printers for Jewelry

The materials used for 3D printed jewelry largely depend on the type of printer being used. SLA printers primarily use photopolymer resins. These resins can perfectly capture minute details and smooth surfaces, making them ideal for complex jewelry designs. Resin-based jewels can later be used in a process called lost wax casting, where the 3D printed piece is covered in plaster, melted out, and then filled with metal.

In terms of DMLS printers, these can fuse a variety of powdered metals and alloys. These include gold, silver, and bronze as well as platinum and stainless steel. Once the printing concludes, no casting is necessary, as the piece is already formed in the chosen metallic material.

Jewelry Design to 3D Printing Process

The process of creating 3D printed jewelry starts with designing a 3D model of the jewelry piece using software tools like CAD (Computer-Aided Design). Once the design is finalized, it’s converted into a file format compatible with the 3D printer, typically STL or OBJ.

The next step is preparing the printer. If it’s an SLA printer, the build plate should be calibrated, the resin vat should be filled, and the correct printing parameters must be selected. If using a DMLS printer, the machine must first be filled with powdered metal.

The 3D printer then constructs the object, layer by layer, until the jewelry piece is created. After printing, the piece undergoes several post-processing steps, including cleaning, curing (in the case of SLA), removal from the build plate, and any necessary polishing or finishing touches.

The Evolution of Jewelry Creation through 3D Printing

3D printing technology has fundamentally transformed the jewelry industry, introducing a new level of detail and intricacy in design. This innovative approach to jewelry making has broken the constraints of conventional methods, unlocking a realm of boundless creativity.

Advantages of 3D Printing in Jewelry

Efficient Turnaround Time with 3D Printing in Jewelry

Beyond enhancing design versatility, 3D printing has also substantially expedited the production process in the jewelry industry. Traditional methods such as wax carving, mold creation, casting, and finishing could take weeks to produce just one piece. Now, with the advent of 3D printing, a piece’s production lifecycle has been drastically cut down. The digital design is created using a Computer-Aided Design (CAD) software tool, which is then converted to a printable file for the 3D printer. The printer performs its magic by melting or binding materials layer-by-layer, forming a tangible 3D object. Depending on the design’s complexity, this technique turns a potentially weeks-long process into a matter of mere hours.

Customization Capabilities of 3D Printing

One of the most significant advantages of 3D printing in jewelry making is the ability to customize designs. The process enables jewelers to create unique pieces tailored to the preferences of each customer. Customers can be involved in the design process, seeing the CAD design before it’s printed, and making adjustments to ensure the final product meets their vision. This level of customization was previously unattainable with traditional manufacturing techniques.

Intricate Detailing with 3D Printing

3D printing technology allows for intricate and complex designs that would have been difficult, if not impossible, to achieve with conventional hand carving or moulding techniques. The precision of 3D printers means that fine details, such as intricate geometrical patterns or even inscriptions, can be included in the jewelry design. This opens up new avenues for creativity and innovation, setting 3D printed jewelry apart from traditionally made items.

Cost and Material Efficiency in 3D Printing

In traditional jewelry making, creating a new design involves carving a new mould, an often time-consuming and costly process. However, with 3D printing, the design is created digitally, minimizing the need for additional materials. This digital-first approach not only reduces material waste but also cuts down on necessary labor, leading to significant cost savings. With traditional methods, changes or corrections to a design would often require starting from scratch. Conversely, with a 3D printer, design adjustments are a simple matter of tweaking the digital file.

Moreover, 3D printing in the jewelry industry allows for the use of a variety of materials, including precious metals, plastic, ceramics, and more. This flexibility in materials, combined with the precision of 3D printing, opens up opportunities to create jewelry pieces with unique properties in terms of weight, texture, and appearance.

3D Printing: Pioneering Sustainable Practices

3D printing is capturing the attention of the jewelry industry due to its numerous advantages. Among its selling points is its sustainability compared to traditional manufacturing methods. The additive layering process used in 3D printing only deposits material where it’s necessary. Consequently, it drastically reduces waste. Moreover, many 3D printers are now capable of using recycled materials – a further nod towards sustainable jewelry production.

Case Studies of 3D printed Jewelry

Case Study: How American Pearl Harnessed 3D Printing For Jewelry

An excellent example of 3D printing’s application in jewelry is the leading jeweler, American Pearl. They’ve harnessed the power of these printers to strike gold – literally. They broke free from the confines of traditional jewelry manufacture and pioneered the use of 3D printing for crafting gold jewelry. In their process, a wax prototype of a jewelry piece is 3D printed first – which then serves as a mold. Molten gold or other precious metals are then cast into these molds, resulting in finely crafted 3D printed jewelry. The process increases the speed of production whilst significantly reducing costs.

Case Study 2: Jenny Wu – Bridging Architecture and Jewelry Design

Jenny Wu, an American architect turned jewelry designer, has proven how 3D printing can push boundaries in jewelry design. Her line, LACE, features intricate, avant-garde pieces that would be nearly impossible to create using traditional manufacturing methods. Wu believes that “3D printing allows [her] to push the boundaries of jewelry design in a way that was previously impossible,” emphasizing the infinite possibilities of the technology. Her creations, such as the Catena necklace, have utilized selective laser sintering (SLS) 3D printing to produce complex geometric structures in steel, bronze, and silver.

Case Study 3: Boulton: The Future of Custom-Made Jewelry

Boulton, an emerging brand in the jewelry industry, is paving the way for the future of custom-made jewelry with 3D printing technology. Customers can get directly involved in the design process by customizing their jewelry pieces using an online interface. The designs are then 3D printed in wax, cast in metal, and hand-finished by experienced jewelers. The result is a piece of jewelry that perfectly matches the customer’s individual tastes and preferences. Their work demonstrates the practical application of 3D printing in crafting personalized pieces.

Case Study 4: Cooksongold and EOS – Collaboration for Precious Metal 3D Printing

Cooksongold, a leading supplier of fabricated precious metals, partnered with EOS, a global 3D printing solutions company, to develop the PRECIOUS M 080 – a 3D printer designed specifically for precious metals. This collaboration reflects the industry’s increasing adoption of 3D printing. The PRECIOUS M 080 enables jewelry designers to move beyond the traditional limits of design and create intricate, highly detailed pieces utilizing gold, silver, or other precious metals.

Case Study 5: Swarovski’s Innovative Approach to 3D Printing

Not only confined to traditional jewelry, 3D printing innovation has extended its reach into the sphere of footwear, as demonstrated by the eminent jewelry company, Swarovski. Cooperating with designer Andreia Chaves, Swarovski pushed the boundaries of creativity by crafting a limited-edition, extraordinarily envisioned stiletto shoe referred to as The Invisible Shoe. This unique piece was 3D printed with nylon before being scrupulously decorated with Swarovski crystals. This project demonstrates Swarovski’s capability to adapt to modern technology, all the while maintaining their distinctive aesthetic appeal.

Challenges and Limitations of 3D Printed Jewelry

Challenges: Material Restrictions and Durability Concerns

Despite the fascinating possibilities, 3D printing in the jewelry industry is not without its obstacles. One of the most notable challenges is the current restriction of available materials. Most traditional pieces of jewelry feature metals such as gold, silver, and platinum, or alternatively, gemstones. However, as of now, 3D printers have limitations and can only print materials like stainless steel, bronze, and brass. This restriction limits the scope for reproducing traditional jewelry pieces in preferred metals like gold or platinum.

Additionally, there are valid concerns regarding the durability and longevity of 3D printed jewelry. Although these pieces might be structurally sound, their resilience under daily wear and tear remains questionable. This issue becomes especially significant for items like engagement rings or bracelets which are often worn every day. Traditional jewelry metals are chosen not only for their aesthetic but also for their long-lasting qualities, an aspect in which 3D printed materials might fall short.

Printing Errors and Quality Control

While 3D printing technology has advanced significantly, it’s still prone to errors that can impact the final product’s quality. In 3D printed jewelry, this can result in mistakes that are not just cosmetic, but also structural. Errors may include layer misalignment, which can affect the piece’s structural integrity, or inadequate support that can result in deformation or collapse of the piece during printing.

Moreover, quality control is a big issue, particularly for complex pieces. The layer-by-layer additive process of 3D printing can lead to issues like rough textures or visible layer lines. Traditional polishing methods might not be efficient for smoothing these textures created through 3D printing.

Technical Innovations and Skills Gap

From a technical viewpoint, the challenges involve high cost and long production times, particularly for metals. Even with more affordable printers available, the cost of materials and the length of time needed to print intricate pieces may still be prohibitive for many small businesses or independent artists.

Furthermore, there’s a significant skills gap. While designing for 3D printing is getting more accessible with modern software, there is still a learning curve. Traditional jewelers might lack the technical skills needed to embrace 3D printing technology, requiring education and training.

Environmental Impact

3D printing in jewelry also needs to consider the environmental implications. The process often requires significant energy consumption, and waste generation is an issue when prints fail, which contributes to environmental strain.

The potential of 3D printing to revolutionize the jewelry industry is evident, yet several challenges and limitations need to be addressed to fully leverage its ability to produce unique, durable and aesthetically pleasing jewelry pieces.

The Future of 3D Printing in Jewelry

A Digital Transformation in Jewelry Manufacturing

The jewelry industry stands on the precipice of significant change with the advent of 3D printing. Historically, jewelry production has been a process dominated by traditional techniques such as casting and artisan-centric manual crafting. However, the intervention of 3D printing signals the onset of a digital revolution in the industry, opening the gate to novel manufacturing approaches and affording unique benefits.

Precision and Design Versatility

3D printing precision is unmatched with traditional manufacturing methods. It allows jewelers to design complex, intricate shapes and structures more accurately and comparatively faster. With technology advancement, the scope of using different materials and customization can significantly expand, offering customers more options in terms of design, personalization, size, and type of metal or gem.

Affordable Prototyping

3D printing has the potential to turn the labor-intensive, expensive prototype development process into a much more straightforward, affordable task. Detailed, wearable prototypes could be made within a few hours. Rapid prototyping allows jewelers to develop models easily, make corrections if needed, and create the final product more effectively, thus minimizing errors and expenses.

Reduction in Wastage

Traditional jewelry making involves cutting shapes out of precious materials, resulting in considerable material wastage. Contrarily, 3D printed jewelry uses just the needed amount of material. Apart from cost-effectiveness, the process is also environmentally sustainable, an aspect that finds increasing resonance with the conscious consumer base.

Effect on Traditional Manufacturing Techniques

While 3D printing is revolutionizing the way we create jewelry, traditional handcrafting techniques maintain their charm since the skills demonstrated by artisans often hold a lot of value and emotional core for customers. However, a blend of both the age-old craftsmanship and new-age technology can ensure exceptional jewelry quality with proficiency.

Future of 3D Printing in Jewelry

As technology evolves, 3D printing could pave the way for further advancements like printing with multiple materials in a single print cycle or even functional movable parts. Direct-metal laser sintering, stereolithography and selective laser melting are gaining popularity amongst 3D printing techniques. This might also enable artists to create their unique designs and market them directly to consumers, reducing the reliance on major manufacturers and creating a more decentralized marketplace.

Use Cases in Restoration and Replication

Another potential advantage is in the realm of jewelry restoration and duplication. With 3D scanning and printing, an accurate replica of vintage or antique jewelry could be created or a damaged piece could be restored back to its original design. This potential future use case offers an exciting prospect in the field of jewelry conservation and antique jewelry recreation.

Jewelry Personalization

Future use scenarios also include the rise of bespoke jewelry as more consumers lean towards personalization. With the 3D printing ability to create intricate, unique designs, customers will be able to tailor their jewelry down to the smallest detail, such as inscriptions, symbols, or unique shapes, leading to true customization.

The fusion of 3D printing technology and jewelry creation is an exciting frontier teeming with endless possibilities. As we’ve explored in this discussion, the technology is not just altering how jewelry is created but also how it’s conceptualized and personalized. Despite the current challenges and limitations, 3D printing continues to push the boundaries, promising a future filled with enhancements and new opportunities. In time, the issues of durability and printing errors will likely diminish with technology advancements, allowing us to focus more on creativity and innovation. The journey of 3D printed jewelry is far from over; if anything, it has just begun. Above all, the shared narrative of 3D printing and jewelry is not merely about streamlining manufacturing or customization. It’s a testament to human ingenuity and the limitless potential that lies at the intersection of technology and creativity.